|

| |

|

June 22, 2003

As a trial run, I decided

to start sanding part of the hull. I was sick of working inside the

boat, and thought I'd do something else for a change. To begin, I

set up some staging along one side of the hull, positioned to give me a

good working height on the entire height of the topsides. |

|

|

| Not knowing how the paint would

sand, I began at the starboard bow with my trusty Porter Cable 5"

random orbit DA sander equipped with an 80 grit disc. Although the

80 grit worked, it soon became apparent that it was too slow, and I had

difficulty breaking through the outer layers of blue paint easily. |

|

I

switched to 40 grit paper, tentatively because I didn't want to

create a mess. However, even the 40 grit took a long time to get

through the outer layers of blue paint that were on the hull--it's tough

stuff, whatever it is. Beneath the blue paint I found a layer of

white material--at first I thought it was paint (and it still could be),

but the more I sanded, the more I thought it was some sort of all-over

fairing filler. Beneath the white layer was the original blue

gelcoat. I

switched to 40 grit paper, tentatively because I didn't want to

create a mess. However, even the 40 grit took a long time to get

through the outer layers of blue paint that were on the hull--it's tough

stuff, whatever it is. Beneath the blue paint I found a layer of

white material--at first I thought it was paint (and it still could be),

but the more I sanded, the more I thought it was some sort of all-over

fairing filler. Beneath the white layer was the original blue

gelcoat.

|

|

Not wanting to scar the soft gelcoat too badly with the 40 grit paper, I

only used the coarser paper to break through the paint and into the white

layer. Once I had a section of about 6 linear feet

sanded in this manner, I decided to try some 80 grit to remove the rest of

the material down to bare gelcoat. This worked fairly

well. As I sanded away the white stuff, a series of gouges and half

moons (all filled with white) appeared. It seems that an overzealous

person in the past butchered the hull with an angle grinder, which damage

someone then had to fill with this white fairing material. To their

credit, they seemed to do a pretty good job fairing, as I hadn't noticed

any of these gouges beneath the blue paint.

|

|

|

|

Sanding this 6'-8' area

from gunwale to waterline took me between an hour and an

hour-and-a-half. I would have continued, but it began to rain, so I

had to put the electric tools away. |

|

July 22, 2003

Click on the outlined small

photos for a full size image.

It was mere coincidence

that I happened to next attack hull grinding exactly a month after my

first day. On this day, I decided to plunge ahead with stripping the

bottom paint--one of the nastiest jobs around, and one that I deemed to be

far easier to handle with the boat outside then closed up in a barn.

A finer, more powdery dust has not been created, I think, than that coming

off a grinder against old-fashioned bottom paint. Yuck. I

didn't have any Tyvek suits, and I'm not much of one to wear them anyway

(particularly in summer heat),

so I put on my work shorts and shirt and installed new cartridges in my

trusty 3M full facepiece respirator. This thing is a Godsend. It was mere coincidence

that I happened to next attack hull grinding exactly a month after my

first day. On this day, I decided to plunge ahead with stripping the

bottom paint--one of the nastiest jobs around, and one that I deemed to be

far easier to handle with the boat outside then closed up in a barn.

A finer, more powdery dust has not been created, I think, than that coming

off a grinder against old-fashioned bottom paint. Yuck. I

didn't have any Tyvek suits, and I'm not much of one to wear them anyway

(particularly in summer heat),

so I put on my work shorts and shirt and installed new cartridges in my

trusty 3M full facepiece respirator. This thing is a Godsend.

|

|

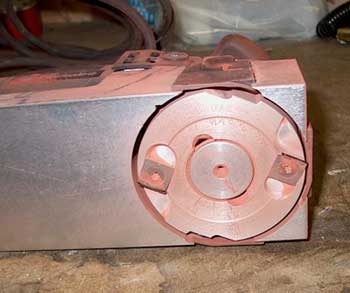

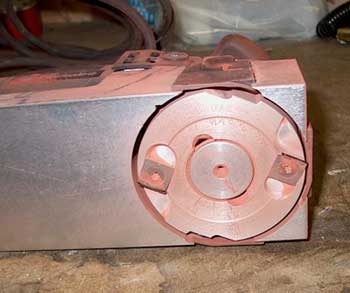

I began work with no

expectations for how far I might get. It was just a good day for the

job, and I figured I'd get done whatever I could. I had a new tool

in the arsenal this time: a borrowed Metabo paint stripping tool,

which features a flush disc onto which are installed a pair of tiny, sharp

blades. When the heavy disc spins at high RPMs, the small blades

take off a nice even layer. A few minutes' testing revealed that the

tool worked fairly well on loose, flaking paint with substantial

thickness; the blades like to have a distinct edge to grip onto. The

test also revealed that the thing was much too heavy for its size; I never

determined what made the blasted thing so heavy. Nonetheless, it

worked quite well and, with a Shopvac attached to the dust collection

port, remained as dustless as possible--which is to say, pretty

dusty. But better than without! I began work with no

expectations for how far I might get. It was just a good day for the

job, and I figured I'd get done whatever I could. I had a new tool

in the arsenal this time: a borrowed Metabo paint stripping tool,

which features a flush disc onto which are installed a pair of tiny, sharp

blades. When the heavy disc spins at high RPMs, the small blades

take off a nice even layer. A few minutes' testing revealed that the

tool worked fairly well on loose, flaking paint with substantial

thickness; the blades like to have a distinct edge to grip onto. The

test also revealed that the thing was much too heavy for its size; I never

determined what made the blasted thing so heavy. Nonetheless, it

worked quite well and, with a Shopvac attached to the dust collection

port, remained as dustless as possible--which is to say, pretty

dusty. But better than without!

|

With the long, flat, heavy

base, the tool is best on flat surfaces. Therefore, it would be best

at stripping barges. Still, there are enough relatively flat

surfaces on a boat hull to enable the tool to work effectively. On

my Triton, I found I could effectively use the tool from the waterline

down to the garboard, where the curvature became too extreme. Other

than the high weight of the tool, it worked very well on this area, and it

didn't take long at all to strip nearly all the paint off the bottom from

the bow to the stern, and down to the garboard. I dug the tool in

too much in one area and shortly thereafter noticed that one blade was

broken--D'OH! Fortunately, I found that there was a

"spare" blade mounted on the tool--a vertically-oriented blade

that I did not need for my current job. Using a silly star-wrench

that came with the kit, I replaced the broken blade. With the long, flat, heavy

base, the tool is best on flat surfaces. Therefore, it would be best

at stripping barges. Still, there are enough relatively flat

surfaces on a boat hull to enable the tool to work effectively. On

my Triton, I found I could effectively use the tool from the waterline

down to the garboard, where the curvature became too extreme. Other

than the high weight of the tool, it worked very well on this area, and it

didn't take long at all to strip nearly all the paint off the bottom from

the bow to the stern, and down to the garboard. I dug the tool in

too much in one area and shortly thereafter noticed that one blade was

broken--D'OH! Fortunately, I found that there was a

"spare" blade mounted on the tool--a vertically-oriented blade

that I did not need for my current job. Using a silly star-wrench

that came with the kit, I replaced the broken blade. |

|

Immediately, the tool

seemed to work better. However, in a few areas, I had some minor

trouble with the tool gouging a bit too far into the hull and

gelcoat--this seemed to be more of a technique issue than a problem with

the tool, however, and I soon got over it. I tried to adjust the

depth of the cut a bit shallower, but amazingly the adjustment required a different

size and type tool (an Allen wrench) than the star wrench included with the kit

for removing the blades (why, oh why, do tool

manufacturers insist on perpetuating this ridiculous habit?), and I didn't

happen to have one of the right size around (figures).

Ignoring the depth, I

pressed on, and found that a slight adjustment of my technique made all

the difference. The tool made incredibly short work of the dry, flaking

paint. Before long, I had done as much on one side as I could, so I

continued with the other side. Now that I had the hang of the tool,

the second side of the hull went even more quickly, and soon I was

done. The stripping tool removed most of the paint from the hull,

but left a very thin layer right against the gelcoat--a layer that proved

to be very easy to sand off with a grinder. Ignoring the depth, I

pressed on, and found that a slight adjustment of my technique made all

the difference. The tool made incredibly short work of the dry, flaking

paint. Before long, I had done as much on one side as I could, so I

continued with the other side. Now that I had the hang of the tool,

the second side of the hull went even more quickly, and soon I was

done. The stripping tool removed most of the paint from the hull,

but left a very thin layer right against the gelcoat--a layer that proved

to be very easy to sand off with a grinder.

After cleaning myself up a

bit--the dust and grit was thick on my arms and clothing--I decided that,

since I was all covered in red dust anyway, I might as well pull out my

big 8" grinder and see what sort of damage I could do to the

remaining paint on the bottom. At first, though, I thought I'd be

off the hook, as I couldn't find any discs to go with the grinder. I

wasn't altogether unhappy with this, but then I found three 40-grit discs

in the bottom of my sanding box. Sighing inwardly, I realized that I

simply had to sand until my three discs were spent.

It's funny how things seem

to work. Now, if I'd had a big box of sanding discs, I probably

would have ended up losing a dozen from bad spin-offs, tears, or other

problems, and the paint would have gummed them up at a horrific

rate. Instead, since I had only three, I was slack-jawed in

amazement (or maybe it was a copper dust-induced stupor) to find

that I could remove nearly all the remaining paint from one side of the

hull using only one disc. I concentrated on the lower portions

first--those that the stripper hadn't been able to touch. It's funny how things seem

to work. Now, if I'd had a big box of sanding discs, I probably

would have ended up losing a dozen from bad spin-offs, tears, or other

problems, and the paint would have gummed them up at a horrific

rate. Instead, since I had only three, I was slack-jawed in

amazement (or maybe it was a copper dust-induced stupor) to find

that I could remove nearly all the remaining paint from one side of the

hull using only one disc. I concentrated on the lower portions

first--those that the stripper hadn't been able to touch.

|

|

When those

areas were close to bare (I refrained from sanding too deeply with the big

grinder, lest I do unnecessary damage to the gelcoat), I lightly ran the

grinder over the stripped areas above, removing much of that thin layer of

remaining paint. Then, with a new disc installed, I attacked the

other side. Finally, with the third--and last--disc, I worked on the

ballast keel and false keel deadwood and the complicated and curvaceous

stern area above the rudder. I tore the disc on a sharp edge

somewhere and was

forced to call it quits, since the tool was badly unbalanced with the asymmetrical

disc. When those

areas were close to bare (I refrained from sanding too deeply with the big

grinder, lest I do unnecessary damage to the gelcoat), I lightly ran the

grinder over the stripped areas above, removing much of that thin layer of

remaining paint. Then, with a new disc installed, I attacked the

other side. Finally, with the third--and last--disc, I worked on the

ballast keel and false keel deadwood and the complicated and curvaceous

stern area above the rudder. I tore the disc on a sharp edge

somewhere and was

forced to call it quits, since the tool was badly unbalanced with the asymmetrical

disc.

|

|

I had a heart-stopping

moment of excitement as I neared the stern while grinding the starboard

side. The large full facepiece respirator tends to block my peripheral vision,

and as I stood up after kneeling to sand near the bottom of the keel, my

shoulder hit the aft jackstand. It tipped over! Quickly, I

grabbed the chain connecting it to the other jackstand which, fortunately,

was on the downhill side (and therefore supporting more weight, I

think). Nothing happened, but for a terrifying moment I was sure the

boat might tip. As fast as I could, I replaced the starboard

jackstand, all the while holding the chain just in case the  other one (I

keep wanting to call it the "leeward" one and have to stop

myself from typing it) decided to pull away. Apparently, the stern

area of the boat is so light, relative to the lead bulb on which the boat

is actually resting well forward, that the stands have less downward

pressure on them than usual, making them a bit more prone to tipping. other one (I

keep wanting to call it the "leeward" one and have to stop

myself from typing it) decided to pull away. Apparently, the stern

area of the boat is so light, relative to the lead bulb on which the boat

is actually resting well forward, that the stands have less downward

pressure on them than usual, making them a bit more prone to tipping.

The red paint remaining, as

can be seen in the photos, is but a thin layer, perhaps a single coat or

less, and

will sand off easily with my small, more manageable, 5" DA sander

later. The smaller tool will also allow better control to smooth the

bottom more appropriately for a fair surface. |

|

|

|

July 23, 2003

The next day, I began

sanding the bottom again with my smaller sander and 40 grit paper, to

remove the last traces of old bottom paint and to begin the overall

smoothing process. I sanded nearly the entire starboard side of the

boat, starting at the top of the boottop (removing it) and all the way to

the centerline. The random orbit action of the sander left the

surface smoother and more fair than that left behind by the large circular

grinder--though still harshly scratched from the coarse paper.

Underneath the boat, and

wearing my full facepiece respirator and hearing protection, I was in my

own world. I happened to look up just before I would have finished

sanding the entire side, only to notice that we were in the midst of a

downpour! With rainwater beginning to run down the hull, soak the

ground, and fall through the open through hull fittings above where I was

working, I decided it was less important to finish the sanding of the

starboard side rather than risk electrocution when my uninsulated

metal-body sander got inevitably wet, so I was forced to pack up the tools

and run quickly for shelter. The heavy rain shower lasted only a

short while, but by the time it ended the ground was saturated with

standing water, and, as I had been too filthy from sanding dust to do

anything else, I had already taken a shower to clean up, and didn't want

to begin sanding again. I decided it would be OK to finish the small

remaining area on another day, when I sanded the port side.

|

|

|

|

|

July 24, 2003

I finished the bottom

stripping/sanding on the starboard side, and then worked to complete the

40-grit sanding on the port side as well. I had a new shipment of

sandpaper from good ol' McMaster-Carr, so I used the big grinder to finish

removing the bulk of the paint from the port side of the keel as

well. It felt great to have the nasty bottom stripping over

with. In comparison, sanding the hull paint will be almost pleasant.

|

|

|

|

|

Continue>

|

|

With the long, flat, heavy

base, the tool is best on flat surfaces. Therefore, it would be best

at stripping barges. Still, there are enough relatively flat

surfaces on a boat hull to enable the tool to work effectively. On

my Triton, I found I could effectively use the tool from the waterline

down to the garboard, where the curvature became too extreme. Other

than the high weight of the tool, it worked very well on this area, and it

didn't take long at all to strip nearly all the paint off the bottom from

the bow to the stern, and down to the garboard. I dug the tool in

too much in one area and shortly thereafter noticed that one blade was

broken--D'OH! Fortunately, I found that there was a

"spare" blade mounted on the tool--a vertically-oriented blade

that I did not need for my current job. Using a silly star-wrench

that came with the kit, I replaced the broken blade.

With the long, flat, heavy

base, the tool is best on flat surfaces. Therefore, it would be best

at stripping barges. Still, there are enough relatively flat

surfaces on a boat hull to enable the tool to work effectively. On

my Triton, I found I could effectively use the tool from the waterline

down to the garboard, where the curvature became too extreme. Other

than the high weight of the tool, it worked very well on this area, and it

didn't take long at all to strip nearly all the paint off the bottom from

the bow to the stern, and down to the garboard. I dug the tool in

too much in one area and shortly thereafter noticed that one blade was

broken--D'OH! Fortunately, I found that there was a

"spare" blade mounted on the tool--a vertically-oriented blade

that I did not need for my current job. Using a silly star-wrench

that came with the kit, I replaced the broken blade.

It was mere coincidence

that I happened to next attack hull grinding exactly a month after my

first day. On this day, I decided to plunge ahead with stripping the

bottom paint--one of the nastiest jobs around, and one that I deemed to be

far easier to handle with the boat outside then closed up in a barn.

A finer, more powdery dust has not been created, I think, than that coming

off a grinder against old-fashioned bottom paint. Yuck. I

didn't have any Tyvek suits, and I'm not much of one to wear them anyway

(particularly in summer heat),

so I put on my work shorts and shirt and installed new cartridges in my

trusty 3M full facepiece respirator. This thing is a Godsend.

It was mere coincidence

that I happened to next attack hull grinding exactly a month after my

first day. On this day, I decided to plunge ahead with stripping the

bottom paint--one of the nastiest jobs around, and one that I deemed to be

far easier to handle with the boat outside then closed up in a barn.

A finer, more powdery dust has not been created, I think, than that coming

off a grinder against old-fashioned bottom paint. Yuck. I

didn't have any Tyvek suits, and I'm not much of one to wear them anyway

(particularly in summer heat),

so I put on my work shorts and shirt and installed new cartridges in my

trusty 3M full facepiece respirator. This thing is a Godsend.