November 12, 2018

Skeedeen 17

Saturday, Sunday, Monday

Over the weekend, I applied two additional coats of varnish to everything as needed, wrapping up the maintenance varnish work.

On Saturday, I sanded and applied a fifth coat on toerails, sixth on the hatch surround, and the second maintenance coat on the companionway pieces:

Sunday, I finished up with the sixth coat on toerails and seventh on the hatch surround (I had a holiday in the sixth coat). I took the photos below the next morning, after I’d removed the masking tape following the final coats.

With the varnish work complete, and the masking tape cleaned up, I turned to the next job on my list, which was to finish up the new nonskid paint for the decks. This meant that I spent the day masking.

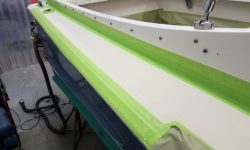

My past experiences with KiwiGrip, which is an extremely thick water-based acrylic paint with a consistency like sour cream that works as a nonskid because it is laid down in a heavy texture with a special roller, had proven that the paint is messy in application, so I took the extra precaution of adding swaths of masking paper and additional masking tape to give me added protection against the inevitable splatter from the application process. Also, because it’s required to remove the masking tape while the paint is still wet, I planned my masking with easy removal in mind, particularly in the cockpit, where lack of access after painting meant that I’d need to remove tape section by section as I went; the tape removal is also a messy proposition, so I hoped these steps would minimize collateral damage.

I also found, during my early experiences with the product, that it didn’t cover adequately in the single coat called for in the directions–and the first time I learned this, it meant that I had to go back and remask everything again. So with that experience under my belt, and unamused by it, I tried some experiments on test pieces first, and then on an actual boat, by applying the coating with a regular non-textured roller first, just to lay down a consistent base coat of the new color, and which didn’t require unmasking. Then, once it cured, I could do the texture coat over the top, completing the job. This worked successfully, and I’d followed this procedure each time I’d used the product since–and would do so in this case as well.

To give me access to the portion of the deck beneath the engine box, I raised it partially and tied it to the bimini frame, which still allowed me access to all areas as well as to the engine box top itself.

On the sidedecks, the toerail varnish was still fresh, so I didn’t mask directly to it in any areas, choosing instead to cover it with masking paper.

Once I’d masked all the borders, following the existing lines and pattern (but fairing by eye when I could, since the existing lines were anything but consistent), I finished up the nonskid prep by cleaning and solvent-washing all the deck surfaces, leaving things ready for the first flat coat of paint next time.

Total time billed on this job over three days: 9 hours

0600 Weather Observation: 36°, rain. Forecast for the day: Showers, clearing late. 45° (Saturday)