|

|

~MENU~ |

| Home |

| The Concept |

| The Boat |

| Bringing Her Home |

|

Weekly Progress Log |

|

Daysailor Projects |

| The Boat Barn |

| Resources |

| Other Sites |

| Email Tim |

|

|

| Boat Barn: Insulation, Windows, and Doors | ||

Along with the electrical installation and wiring, I chose to do all the work on the windows, doors, and insulation in the barn. |

Framing | |

| Raising the Walls | ||

| Roof and Trim | ||

| Electrical | ||

| Insulation/Windows/Doors Clerestory Windows Back Windows Man Door Insulation Vapor Barrier Plastic Rolling Barn Doors |

||

| Barn

Home Page

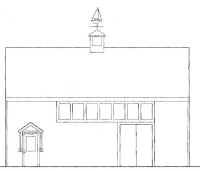

For a time, I debated how many--or if indeed any--windows I would install in the barn at this time. Duh. Of course, I ended up deciding that I needed to install all seven clerestory windows, in part because the two end openings had been partially cut open while the walls were raised with the crane. Because I wanted to retain the consistent look of the full row of windows, this more or less forced my hand into installing all seven; I had been considering doing five. No worry, though, as the windows I had chosen previously (so that the rough openings could be properly framed) were inexpensive enough that I could splurge on a large number of them. And in the end, the windows will make the barn, both from an appearance standpoint outside, as well as from a functionality standpoint inside. |

|

With each window marked, I cut out the plywood sheathing/siding with my small circular saw, with the blade set to just over 3/4" in depth. (The siding is 3/4".) Then, I plunged the blade into the siding and cut out the openings, one at a time, until all seven were complete. My blade, the only one I had on hand, was dull to begin with, but was really dull by the time I reached the last opening. Needless to say, I was glad to be done with it! |

|

|

|

I installed the windows several days later. Bob had his aluminum jack staging set up on the south wall, and I couldn't pass up such a convenient opportunity. The windows I chose are simple sliding vinyl windows, 3' x 3', with a nailing flange that makes installation a breeze.

|

|

I couldn't resist installing all five of the planned windows in the back wall. I had entertained the idea of adding a couple, or waiting altogether until another time. However, after seeing the difference the clerestory windows made, I threw the budget out the window and bought five more of the same windows for the back wall. Easy come, easy go. I followed the same installation procedure as detailed above, although it was significantly easier this time because the windows were much closer to the ground--and I used a different saw with a good blade, powered with a short cord from the barn outlets. Oh, how nice the windows were. I was instantly glad I installed them. The barn is located in the corner of the property nearest our back neighbor, which happens to be an attractive cape style with a pond right on the property line. Interestingly enough, the barn now commands the best views on our property, with pleasing glances of the pond and stream through the new back windows. |

|

|