110 Cookson Lane | Whitefield, ME 04353 | 207-232-7600 | tim@lackeysailing.com

Ashantee | Wednesday, December 17, 2014

It's uncanny how often something that resisted all attempts at the end of one day turns into a "nothing" job on the next. So it was with the winch bases, which had seemed immobile, but with a new day, and a new approach (a flat bar), I found that the winch bases released from the deck without much issue, once I broke the seal of the gobs of silicone beneath. I didn't even bother disassembling the starboard winch for now, since I knew I'd never get the fasteners out, so I just pried the base up as is.

The only way the winches themselves could be freed from the bases was by cutting the bolts, which were rusted (galvanized steel carriage bolts) and completely jammed within the thick wooden bases. To make cutting easier, I used a chisel to open up the bases around the fastener locations, just below the winch bases, then cut the bolts with a saw.

Back on the boat, I wrapped up the deck hardware removal in the cockpit, where I removed locker hinges, deck plates, and various other installations, including one abandoned push-button switch, which led to my removing the adjacent AC shore power receptacle, although I'd originally thought I'd leave that in place. But it was easy enough to remove. I also unfastened the engine instrument recess and led it--still connected to all its wires--back through the opening into the starboard locker for safekeeping. I removed a cockpit shower, and the old dodger fasteners (which were riveted in place, so I had to drill them out).

One of the handrail fasteners on the port side, above the head, remained sticking up above the deck, as it was apparently buried beneath the overhead liner--how this could be I did not know, but nonetheless it was, with no way to push it through. Till I could get back to it and cut it off or otherwise deal with it, it seemed begging to be kneeled or sat upon, so I added a little green flag to help me notice it.

There was a manual bilge pump attached through the cockpit sole, just forward of the fuel tank fill. With known softness around the fuel fill, I'd soon be working in this area, but for now I hoped to avoid removing the bilge pump (as well as the fuel fitting) as access was tough. Later, I'd deal with these as the need arose.

With all the hardware off the deck, I turned to the deadlights. These were the standard (for this vintage boat) two-piece bronze frames secured together with half-blind fasteners with a lens captured between the two, floating more or less in the void between the frames. Past experience with this sort of installation demanded that I keep the fasteners and frames in their exact orientation at all times, so as I removed the fasteners from outside I placed them in order on the deck. Once I removed the frames from both sides, I reassembled each set with the fasteners back in their proper locations. I repeated this process for all four deadlights.

Next, I removed the six opening ports, following the same basic process and keeping the fasteners in order even though it probably mattered less here, as these ports' fasteners went through the frames and didn't dead-end within. But it never hurt to be sure, and in any event some of the fasteners were of different lengths.

Inside the cabin, I removed various bits of small hardware from the overhead to prepare for the eventual sanding and painting.

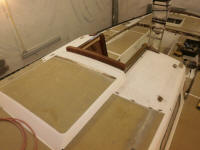

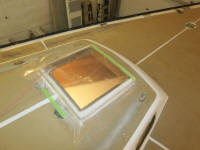

To keep most of the dust and debris out of the cabin during the upcoming bulk hull and deck sanding and repairs, I covered all the port openings with some paper, and draped some plastic over the forward hatch and companionway that would still allow inside access, but keep out the worst of it. I also covered up for protection the sailing and navigation instruments in the cockpit.

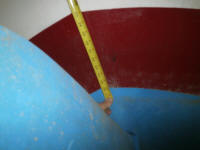

Planning to start work on the hull and move my way up, using known and re-creatable points on the boat I documented the existing positions of the waterline (bottom paint) and boottop at stem and stern, noting also the positions of the visible scum lines for future reference in restriking these lines much later in the process. Now I could sand away with abandon.

Total Time Billed on This Job Today: 8

Hours