110 Cookson Lane | Whitefield, ME 04353 | 207-232-7600 | tim@lackeysailing.com

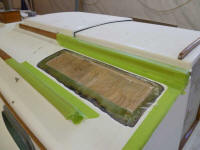

After removing the weights and plastic from the newly-cored areas, I inspected each area to ensure that the core was well bonded and secure.

Next, I washed the exposed epoxy, then sanded the areas as needed to prepare for additional steps, lightly scuffing the new epoxy and evening out the seams between core and adjacent deck areas.

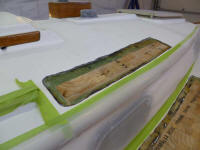

I made paper patterns of each area, running the pattern nearly out to the edge of the ground tapers of each patch, and used the patterns to cut two layers of biaxial fiberglass cloth to the appropriate sizes and shapes. Two layers would approximate the thickness of the existing top skin, with the first layer full-size to extend to the edges of the tapered edge areas, and the second layer roughly 1" inside of that.

I filled a few low spots at the edges of the new core with thickened epoxy, then wet out the top surface of the core in all areas before wetting out and installing the two new layers of fiberglass.

Total Time on This Job Today: 4.75 hours